DIAMON-FUSION® COATING FOR

CLEANING ELECTRICAL INSULATORS

The nanotechnology within the Diamon-Fusion® coating improves the performance of insulators, with a focus on durability, longevity, effectiveness, expense, and ease of application. When applied to glass and ceramic insulators, Diamon-Fusion® reduces the adherence of water, salt, dirt, and other contaminants to the surface of insulator.

The nanotechnology within the Diamon-Fusion® coating improves the performance of insulators, with a focus on durability, longevity, effectiveness, expense, and ease of application. When applied to glass and ceramic insulators, Diamon-Fusion® reduces the adherence of water, salt, dirt, and other contaminants to the surface of insulator.

GLOBAL PROJECTS

Diamon-Fusion® protective coating has been applied to prestigious landmarks around the world keeping the glass looking like-new with minimal maintenance.

THE BEST PROTECTIVE COATING FOR

CLEANING CERAMIC INSULATORS

Unlike existing coating methods, Diamon-Fusion® reduces the buildup of contaminants that could lead to flash overs and system outages. The covalent bond (which won’t peel, chip, or crack) is meant to create higher adherence, which would indicate the coating would last longer, as well as improve energy efficiencies. Having a low-maintenance coating solution leads to less onsite repairs and downtime for cleaning. Use the slider below to see how Diamon-Fusion® easily repels water (from laying flat to beading up).

THE BEST PROTECTIVE COATING FOR CLEANING CERAMIC INSULATORS

Unlike existing coating methods, Diamon-Fusion® reduces the buildup of contaminants that could lead to flash overs and system outages. The covalent bond (which won’t peel, chip, or crack) is meant to create higher adherence, which would indicate the coating would last longer, as well as improve energy efficiencies. Having a low-maintenance coating solution leads to less onsite repairs and downtime for cleaning. Use the slider below to see how Diamon-Fusion® easily repels water (from laying flat to beading up).

THE BEST PROTECTIVE COATING FOR CLEANING CERAMIC INSULATORS

Unlike existing coating methods, Diamon-Fusion® reduces the buildup of contaminants that could lead to flash overs and system outages. The covalent bond (which won’t peel, chip, or crack) is meant to create higher adherence, which would indicate the coating would last longer, as well as improve energy efficiencies. Having a low-maintenance coating solution leads to less onsite repairs and downtime for cleaning. Use the slider below to see how Diamon-Fusion® easily repels water (from laying flat to beading up).

WHY CHOOSE DIAMON-FUSION®?

Diamon-Fusion® protective coating is the best way to keep electrical, glass, and ceramic insulators clean and protected against environmental pollutants. The patented coating is used by insulator companies, having been applied to thousands of electrical and ceramic insulators, globally.

WHY CHOOSE DIAMON-FUSION®?

Diamon-Fusion® protective coating is the best way to keep electrical, glass, and ceramic insulators clean and protected against environmental pollutants. The patented coating is used by insulator companies, having been applied to thousands of electrical and ceramic insulators, globally.

WHY CHOOSE DIAMON-FUSION®?

Diamon-Fusion® protective coating is the best way to keep electrical, glass, and ceramic insulators clean and protected against environmental pollutants. The patented coating is used by insulator companies, having been applied to thousands of electrical and ceramic insulators, globally.

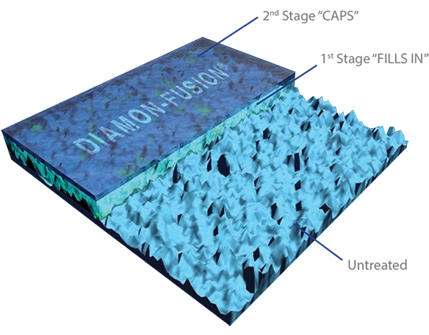

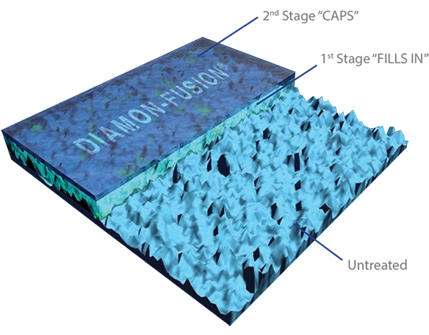

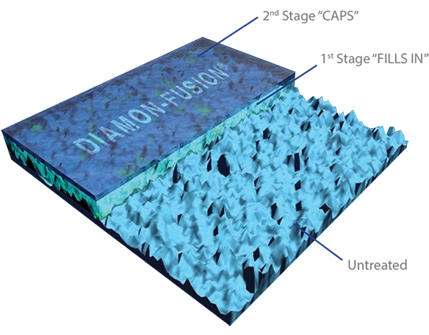

HOW DIAMON-FUSION® WORKS?

Similar to the scientific properties of glass, electrical and ceramic insulators contain microscopic peaks and valleys that allow environmental pollutants to penetrate the surface. Overtime, these contaminants can cause stains and corrosion. Diamon-Fusion® is a hydrophobic treatment process that chemically bonds to the insulator, making it significantly easier to clean.

Tested and approved by: DOWSIL™ Sealants, Sika® Sealants, Intertek, Fenzi, Smith-Emery, and Chemir. CSI Reference Section 09 01 10.92 – Protective Surface Treatments.

To learn more about the benefits and technology behind how Diamon-Fusion® works, download our technical datasheet.

HOW DIAMON-FUSION® WORKS?

Similar to the scientific properties of glass, electrical and ceramic insulators contain microscopic peaks and valleys that allow environmental pollutants to penetrate the surface. Overtime, these contaminants can cause stains and corrosion. Diamon-Fusion® is a hydrophobic treatment process that chemically bonds to the insulator, making it significantly easier to clean.

Tested and approved by: DOWSIL™ Sealants, Sika® Sealants, Intertek, Fenzi, Smith-Emery, and Chemir. CSI Reference Section 09 01 10.92 – Protective Surface Treatments.

To learn more about the benefits and technology behind how Diamon-Fusion® works, download our technical datasheet.

HOW DIAMON-FUSION® WORKS?

Similar to the scientific properties of glass, electrical and ceramic insulators contain microscopic peaks and valleys that allow environmental pollutants to penetrate the surface. Overtime, these contaminants can cause stains and corrosion. Diamon-Fusion® is a hydrophobic treatment process that chemically bonds to the insulator, making it significantly easier to clean.

Tested and approved by: DOWSIL™ Sealants, Sika® Sealants, Intertek, Fenzi, Smith-Emery, and Chemir. CSI Reference Section 09 01 10.92 – Protective Surface Treatments.

To learn more about the benefits and technology behind how Diamon-Fusion® works, download our technical datasheet.

TECHNICAL FEATURES AND BENEFITS

TECHNICAL FEATURES AND BENEFITS

TECHNICAL FEATURES AND BENEFITS

FACTORY/MACHINE APPLICATION

Ensure a professionally applied protective coating through our certified Diamon-Fusion® dealers. All ceramic and electric insulators treated through them are done via machine application, achieving consistent coating coverage, a high degree of quality, and the most cost-effective solution.

DO-IT-YOURSELF PRODUCTS

Having Diamon-Fusion® applied to electrical and ceramic insulators can only be done through DFI’s select network of trained applicators. For applications on insulators that you can do yourself, DFI offers a wide range of cleaning products and protective coatings, including Clear-Fusion™ V, which can be purchased on our e-commerce store at www.shopdfi.com.

FACTORY/MACHINE APPLICATION

Ensure a professionally applied protective coating through our certified Diamon-Fusion® dealers. All ceramic and electric insulators treated through them are done via machine application, achieving consistent coating coverage, a high degree of quality, and the most cost-effective solution.

DO-IT-YOURSELF PRODUCTS

Having Diamon-Fusion® applied to electrical and ceramic insulators can only be done through DFI’s select network of trained applicators. For applications on insulators that you can do yourself, DFI offers a wide range of cleaning products and protective coatings, including Clear-Fusion™ V, which can be purchased on our e-commerce store at www.shopdfi.com.

FACTORY/MACHINE APPLICATION

Ensure a professionally applied protective coating through our certified Diamon-Fusion® dealers. All ceramic and electric insulators treated through them are done via machine application, achieving consistent coating coverage, a high degree of quality, and the most cost-effective solution.

DO-IT-YOURSELF PRODUCTS

Having Diamon-Fusion® applied to electrical and ceramic insulators can only be done through DFI’s select network of trained applicators. For applications on insulators that you can do yourself, DFI offers a wide range of cleaning products and protective coatings, including Clear-Fusion™ V, which can be purchased on our e-commerce store at www.shopdfi.com.

FREQUENTLY ASKED QUESTIONS

How much does it cost to get Diamon-Fusion® applied to electrical insulators?

Prices are determined by DFI resellers according to their own business strategies and market segments. Although prices do vary depending on geographical areas and markets, Diamon-Fusion® has proven to provide the best combination of price and performance of any protective coating available on the market today.

Can Diamon-Fusion® be applied to existing ceramic and glass insulators?

Yes! If you’d like to have your glass and ceramic insulators protected, please contact us for more information.

Will Diamon-Fusion® break down when exposed to sunlight?

Never! Diamon-Fusion® is UV-resistant; so, once it has been applied to ceramic, electrical, or glass insulators it will not break down in sunlight.

FREQUENTLY ASKED QUESTIONS

How much does it cost to get Diamon-Fusion® applied to electrical insulators?

Prices are determined by DFI resellers according to their own business strategies and market segments. Although prices do vary depending on geographical areas and markets, Diamon-Fusion® has proven to provide the best combination of price and performance of any protective coating available on the market today.

Can Diamon-Fusion® be applied to existing ceramic and glass insulators?

Yes! If you’d like to have your glass and ceramic insulators protected, please contact us for more information.

Will Diamon-Fusion® break down when exposed to sunlight?

Never! Diamon-Fusion® is UV-resistant; so, once it has been applied to ceramic, electrical, or glass insulators it will not break down in sunlight.

Have a question? Reach out and contact our team.

Have a question? Reach out and contact our team.